technology.

Minus9 has developed a proprietary microscopic, edible tag called a “mint” (“Micro Item Number Tag”), useful for identification, authentication, quality assurance, supply chain tracking and anti-counterfeiting measures

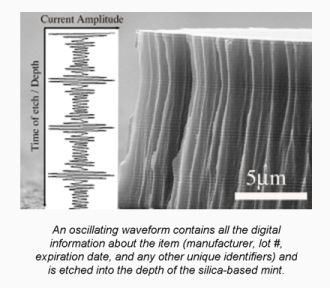

Mints are made from porous silica, generally regarded as safe (GRAS) by the FDA and a naturally-occurring mineral. Each mint contains a unique spectral signature derived from the patented process by which unique physical, spectral ‘barcodes’ are etched onto a porous silicon wafer.

Since mints are encoded with information throughout their depth, rather than along their surface, they can be broken or produced in various shapes, with each particle still containing all of the encoded information. Given silica’s natural robustness and temperature resistance (melting point above 1600°C), mints are ideal for multiple layer security and track and trace applications, including forensics, where they may be subjected to rougher conditions.

Since mints are passive, requiring no power, their shelf-life exceeds that of RFID tags. Furthermore, mints costs only a fraction of a penny to produce and label, which is on order of 1/100th the cost of RFID tags.

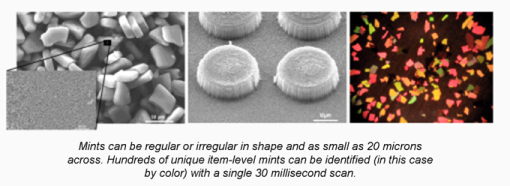

Hi-speed, mobile readers are then capable of reading hundreds of unique mints in less than 30 milliseconds, whether the mint is embedded in an item or read through clear packaging. Given the technology, in-field authentication and forensic capabilities are merged into one simple reading device.

The unique spectral code can also: be verified against other cryptographic information printed on the package, such that the item and packaging are authenticated together; allow for closer producer-customer interaction, in a social networking manner; validate product “freshness” for the consumer; serve as a customer registration process; ensure compliance with medication prescribed by the consumer’s doctor; or even, serve as “whistle blower” program by which consumers can report counterfeiters.

Minus9’s mint technology offers the best of existing track and trace technologies, with none of the drawbacks, at a fraction of the cost:

- Nearly an infinite number of codes can be created

- Broad size range (down to 20 micrometers) allows for both covert and overt tagging

- Low cost – at a fraction of a penny, they are 1/100th the cost of RFID

- Edible, biologically inert (GRAS) and naturally occurring

- Flexibility in manufacturing process integration – no extra equipment as mints™

can be applied via sprays, coatings, inks, varnishes, or as part of laminate - High temperature resistance - melting point above 1600°C

- Passive - no batteries or power required

- Digital, multi-tag read capabilities – hundreds of unique tags can be read and validated

in milliseconds. - Multi-layer security. Can be used in or on a product, package and label or security fiber.

- Producer controls validation. Auto-authentication can reduce the costs and security

risks associated with online databases and maintenance.

Learn more about the closed loop security system or read about “mints™” and their ability to track, trace and authenticate medicine, food products, consumer goods, industrial products or their newest applications.